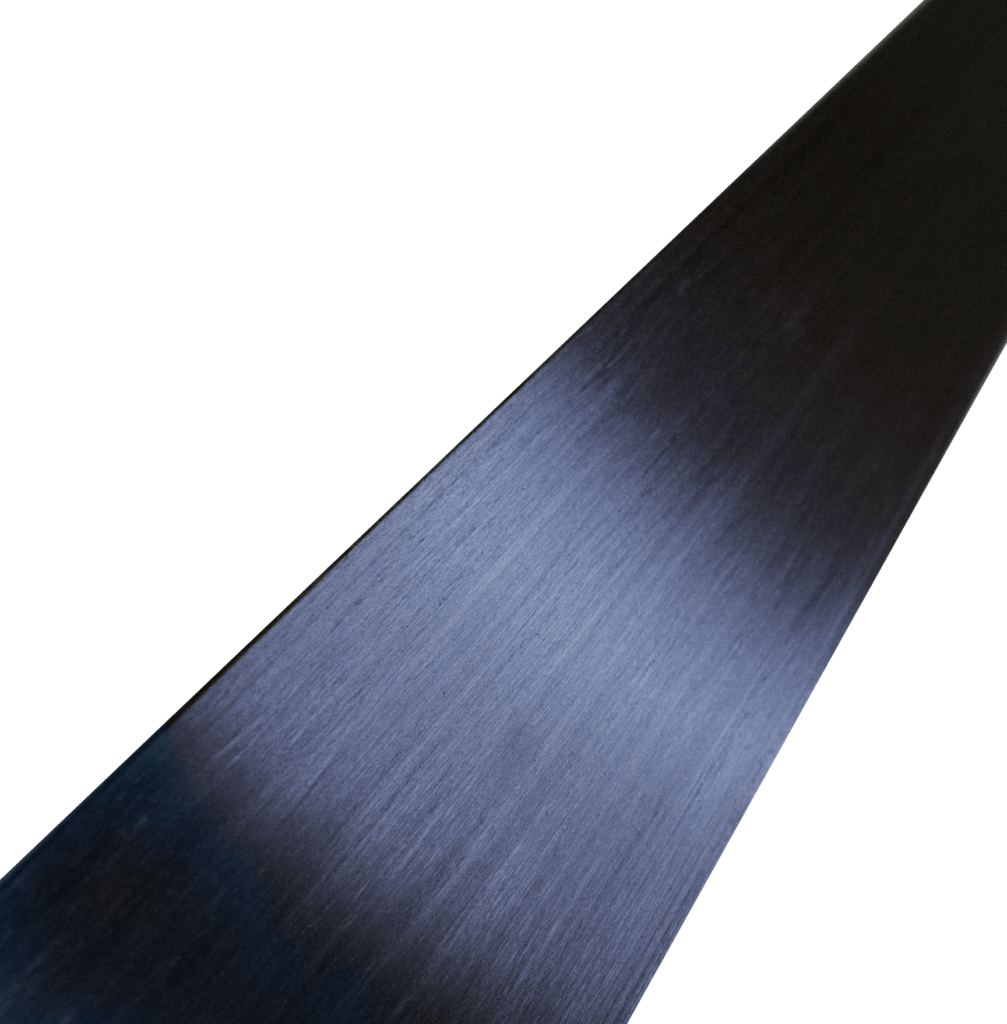

CFRP LAMELLA FOR STRUCTURAL STRENGTHENING

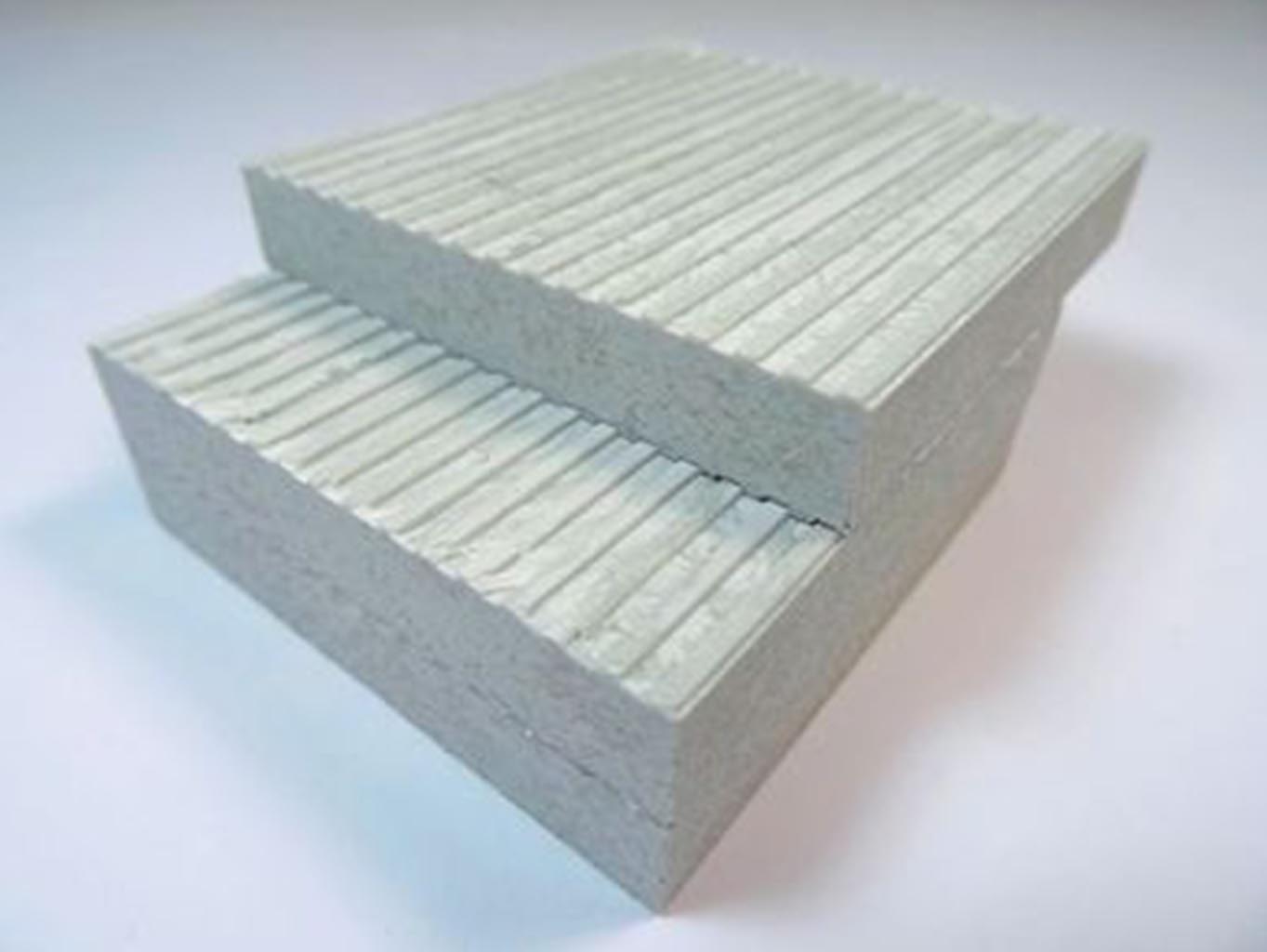

Carbon fiber reinforced plastic (CFRP) is a highly technical material that is not only in great demand in almost all fields of mobility and sports equipment. The extreme tensile strengths of CFRP composite elements also provide elemental benefits in technically highly demanding applications in the construction sector. If the stability of a bridge structure is no longer given due to overload or damage mechanisms, reinforcement measures are necessary. This includes the use of CFRP lamellas, which are bonded to the reinforced concrete surface using suitable adhesive systems while taking into account the technical guidelines and normative requirements of the respective country. While the load on a bridge continues to increase, its service life can be significantly extended by the use of CFRP lamellas. Longer and stronger – that is also sustainability, especially when a material-, labor- and time-intensive new concrete construction is avoided for many years.